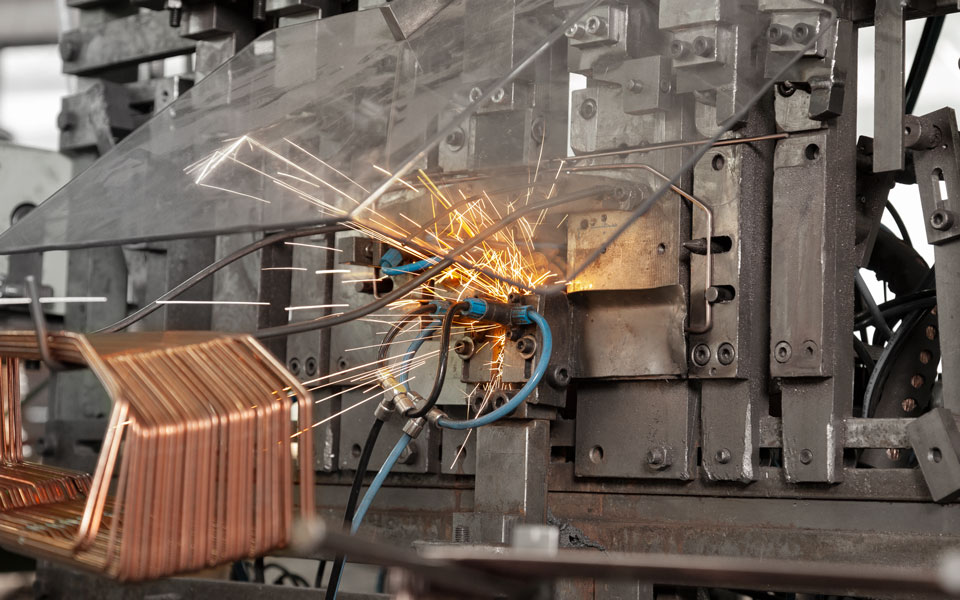

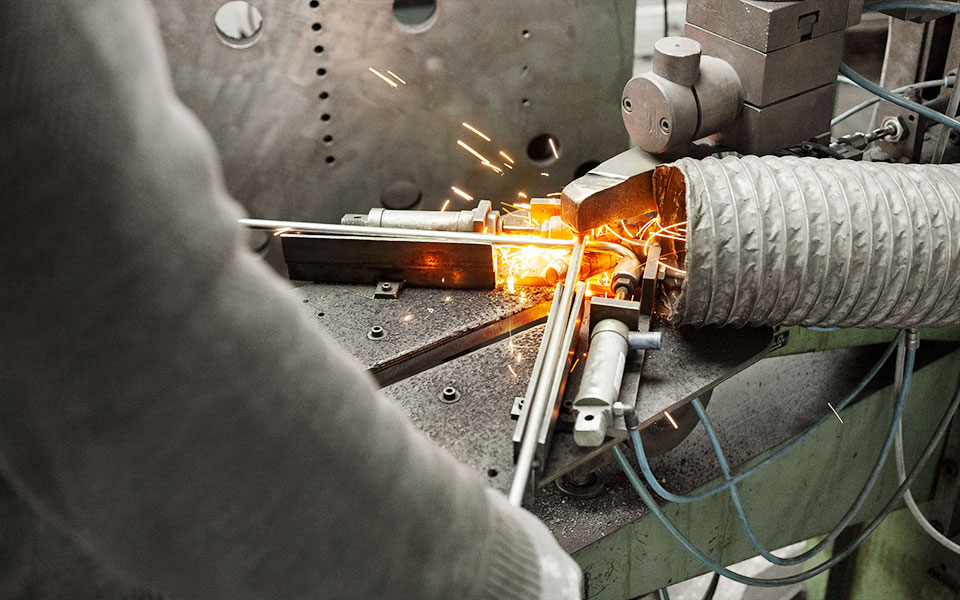

Kreutz & Mock is competence in wire bending. We have been doing this work and business with passion for more than 80 years. A key unique selling point is our machine park with more than 70 different wire bending machines. In our plant in Mainfranken we use numerous machines developed and built by our engineers as an addition to the classic industrial machines. Due to this unique production system, we can also take on special orders and meet highly individual customer requests. With our great experience in wire bending technology we find suitable solutions for every application and realize bent wire parts according to your purposes and needs.

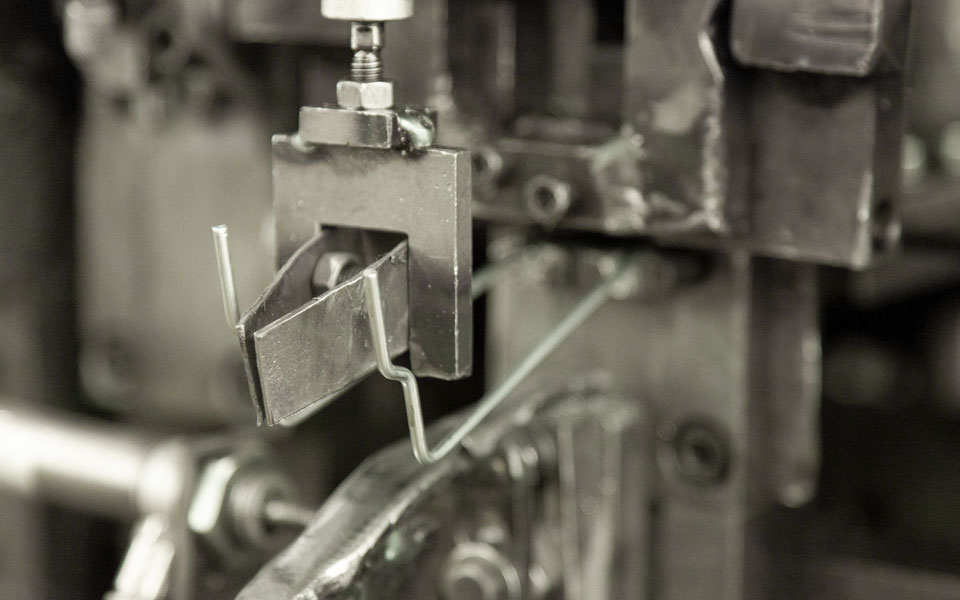

For medium and large series our in-house built machines are first choice. Do you need quantities in the millions or want to process kilometers of wire into individual bent wire parts? Kreutz & Mock will do that for you - quickly, precisely and just in time. Or do you have a more complex or delicate requirement? For small series as well as elaborately designed, three-dimensional wire bending parts we have our CNC-controlled one- and two-head wire bending machines to realize sophisticated high quality solutions for all wires up to a diameter of 13 mm.

Just get in touch, talk to us and tell us what you need. We will surely find a solution that meets your expectations and requirements.

Our machine park, which has grown over many years, combines solid industrial technology with the latest control technology. So we can provide a constantly high quality level and large variety of products every day. In addition, we can guarantee an almost arbitrarily scalable quantity. According to your order, we manufacture small series, individual pieces and prototypes as well as large series with many millions of identical wire bending parts.

On a production space of approx. 3,000 m², our 40 qualified employees process an average of more than 5 tons of wire every day - in the solid, long lasting quality our demanding customers from leading industrial sectors need. This we guarantee through a quality management system according to DIN EN ISO 9001: 2015 and a continuous improvement process that we have integrated in all areas of our company. And, by the way, for more than 20 years now, as our company has been certified for the first time in 1999.

Our machine park processes (almost) all metals: from aluminum, brass, copper or structural steel to spring steel or stainless steel. We also offer various post-processing options for the optimal surface structure of your bent wire parts. Here, too, we can process almost any quantity according to your specifications, from individual pieces to large series. The possibilities range from hot-dip galvanizing and vibratory finishing to anodizing, powder coating, and many more.

Do you want a special color, corrosion protection or burr-free edges? Please feel free to contact us and tell us your specific requirements. We will be happy to advise you personally and find the best solution. In addition to post-processing in-house, we rely on a network of experienced specialists who can do the post-processing on our behalf on a project basis. We have been working together with these external service providers successfully for many years, expanding our range of services and thus going beyond our own core competencies in the field of wire bending technology.