As a manufacturer and service provider, Kreutz & Mock has been offering the highest quality in wire processing for decades. We developed our machine park ourselves and designed it individually so that it perfectly matches our requirements and those of our customers. With the latest CNC technology, we are optimally equipped for the production of small series as well as for mass production. Our process-oriented quality management, innovative and flexible thinking as well as a wide range of goods form a reliable basis on which we develop exactly the solutions that are needed. And our customers can rely on that at any time.

The automotive industry places particularly high demands on its service providers and suppliers. For this reason, we are very proud to also supply this discerning customer base with high-quality bent wire parts. Our quality management system is certified according to DIN EN ISO 9001: 2015 and fulfills the quality requirements and quality assurance according to DIN EN ISO 3834-3 when welding in series and one-off production. We have thus been a proven and reliable partner for automobile manufacturers and their suppliers since the 1990s. Every one of our 40 employees, from trainees to shift supervisors, works every day to confirm the good reputation of our company with the best quality and excellent customer service. Let us convince you of our performance and the quality of our bent wire parts.

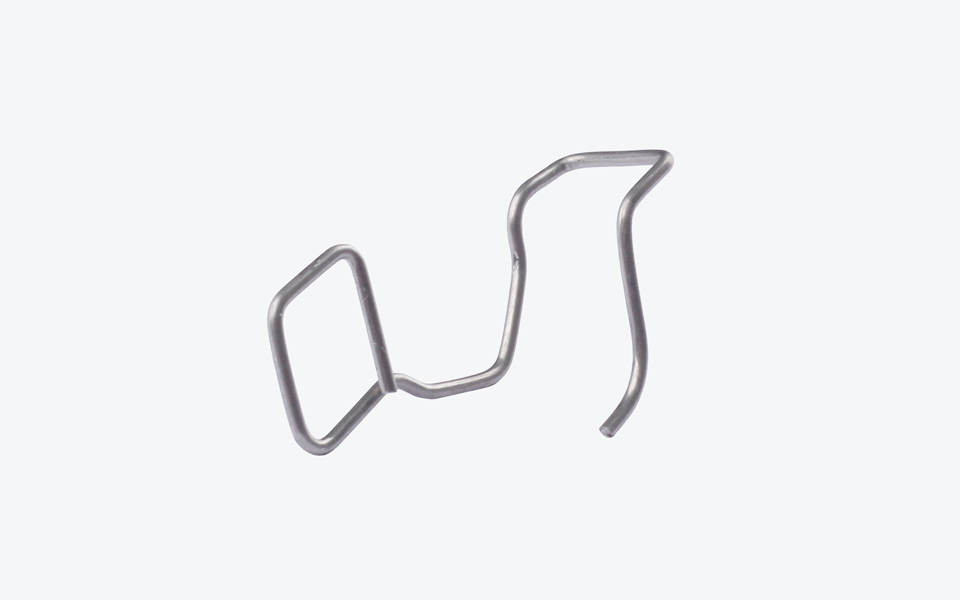

We produce bent wire parts and springs for numerous customers from all areas of the automotive industry. The range of our products ranges from simple retaining springs that are used in the engine or interior, through complex wire frames for the secure attachment of components to compression and tension springs. The parts are installed in headlights, headrests, sun visors and braking systems, among others. Our customers include numerous well-known car manufacturers and renowned suppliers.

Our service also includes various processes for the surface treatment of metal parts and bent wire parts, which we can design and adapt individually for each customer. We also manufacture complete assemblies and then make them available to the respective production in time. The most important characteristics of our company are the consistently high quality of our products, flexibility, reliability and the combination of tradition and innovation. Our machines are computer controlled and our employees are specialists with years of experience. These are the best prerequisites for realizing technically sophisticated solutions, such as those required by the German automotive industry, in order to maintain their leading international position in the future.

Wire bendingWe can process numerous different materials on more than 70 metalworking machines: stainless steel and spring steel in different grades, galvanized or coated wires and also iron and copper wire. We manufacture springs from a wire thickness of 0.1 mm exactly according to our customers' specifications, other wire bending parts from a thickness of 0.7 mm and up to a diameter of 13 mm.

We regard ourselves as a full-service provider. Our core competence lies in forming metal products. We have converted the expertise gained from working with metal into additional services for our customers. We connect metal wires and tubes, manufacture complete assemblies in combination with other materials and give the metals the decisive polish – for example by slide grinding (barrel finishing) or electropolishing.

Surface engineeringWelding technologyComponent assembly